First Article Inspection Form

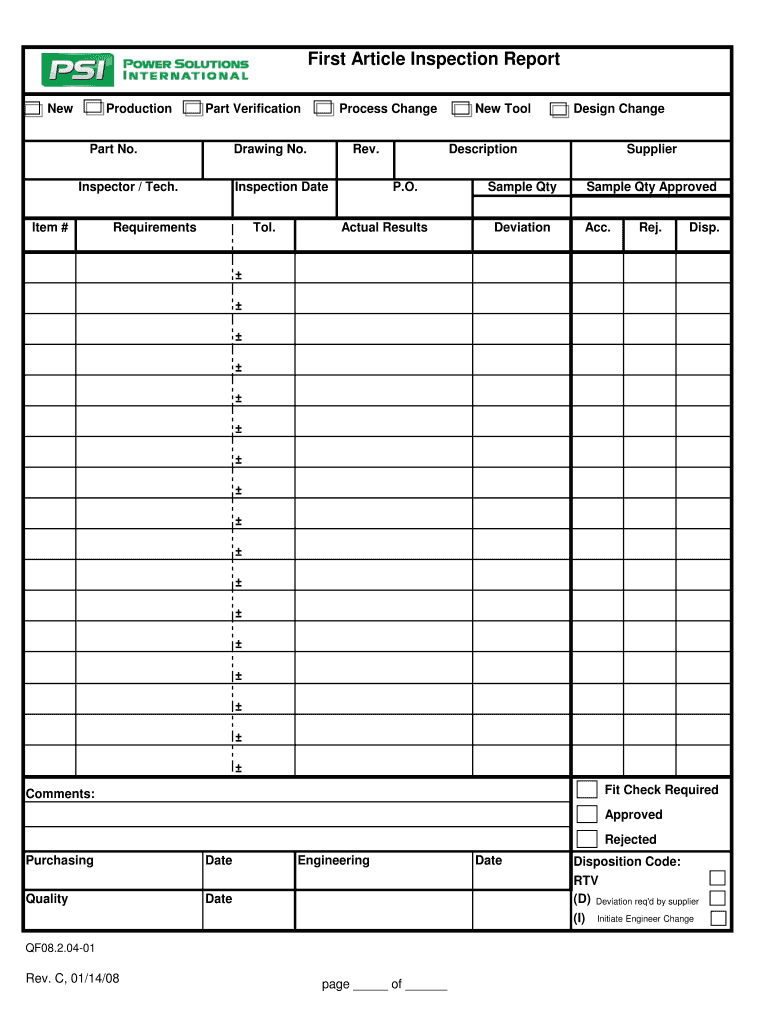

First Article Inspection Form - Learn more about as9102 and download a free as9102 rev b template and this guide as a pdf. What is a first article inspection (fai)? And 5) first article inspection checklist. Digital product definition data sets; Web here's how you can create a first article inspection report in five steps. Web instructions first article inspection (fai) report for form mdc 1016 1. Web download, print or send your completed first article inspection reports as professionally formatted pdf documents with your company logo and colours. 3) first article inspection as9102 form 2; 2) first article inspection as9102 form 1; Part nu mber 2 part name 3.

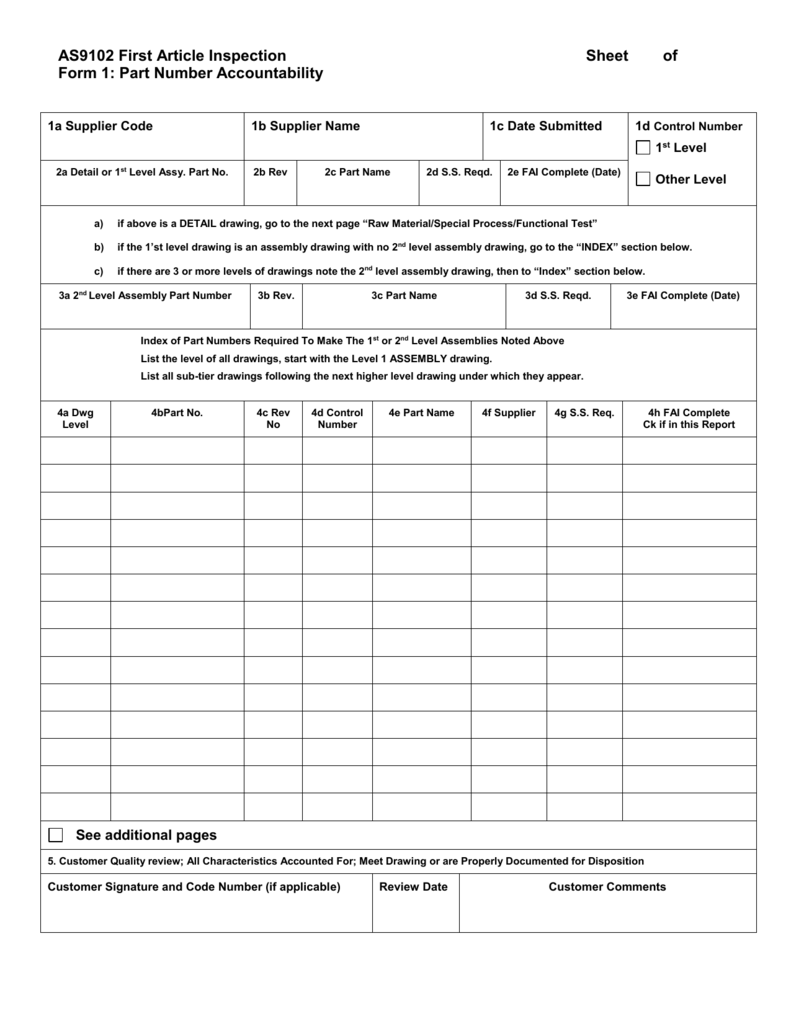

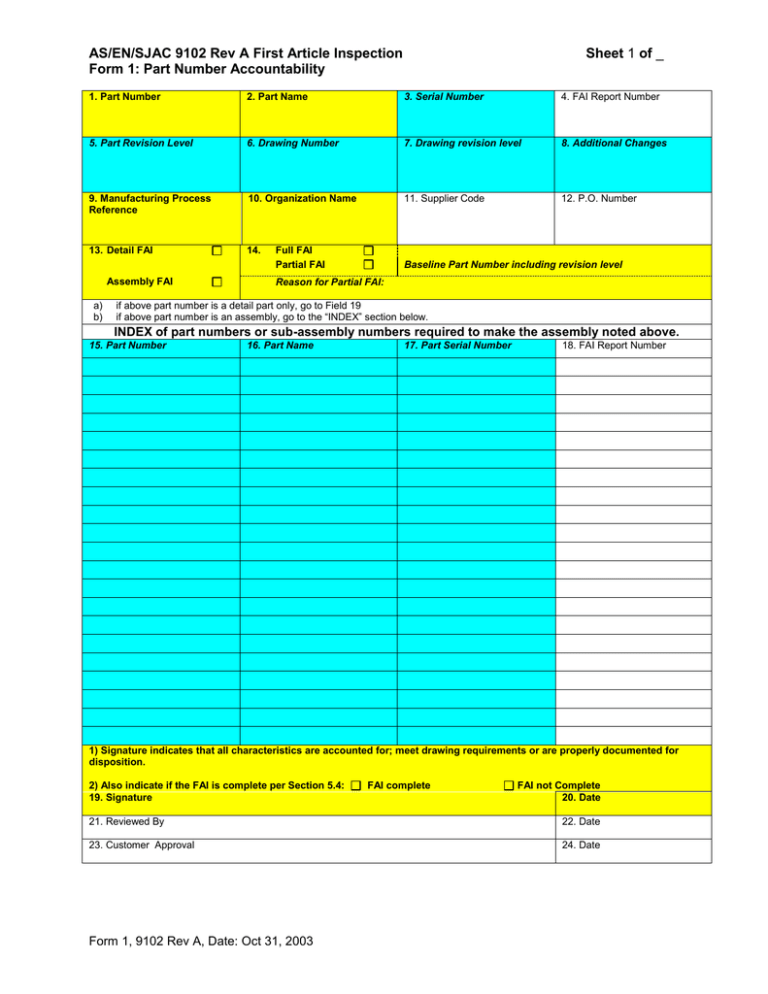

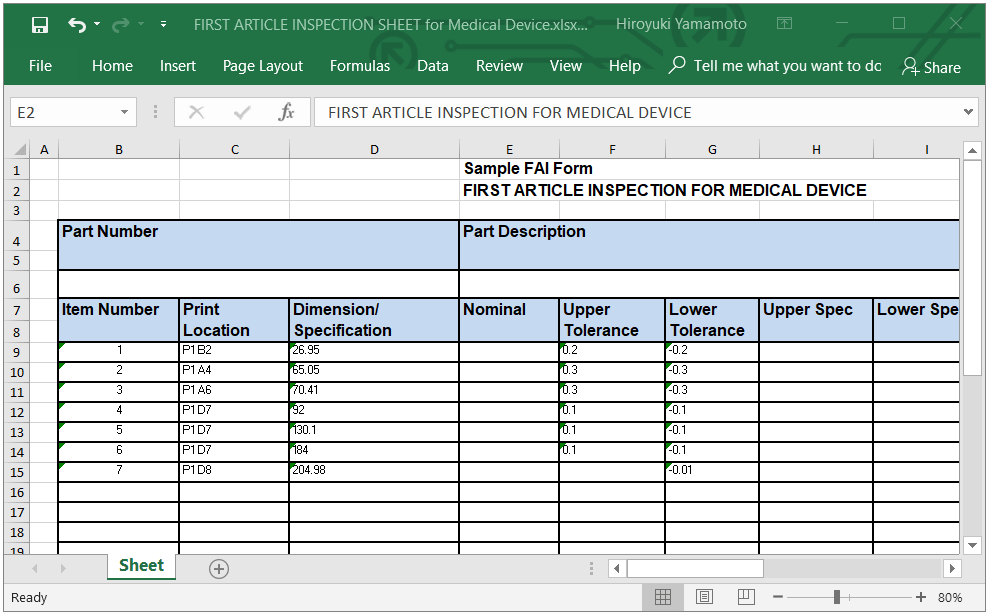

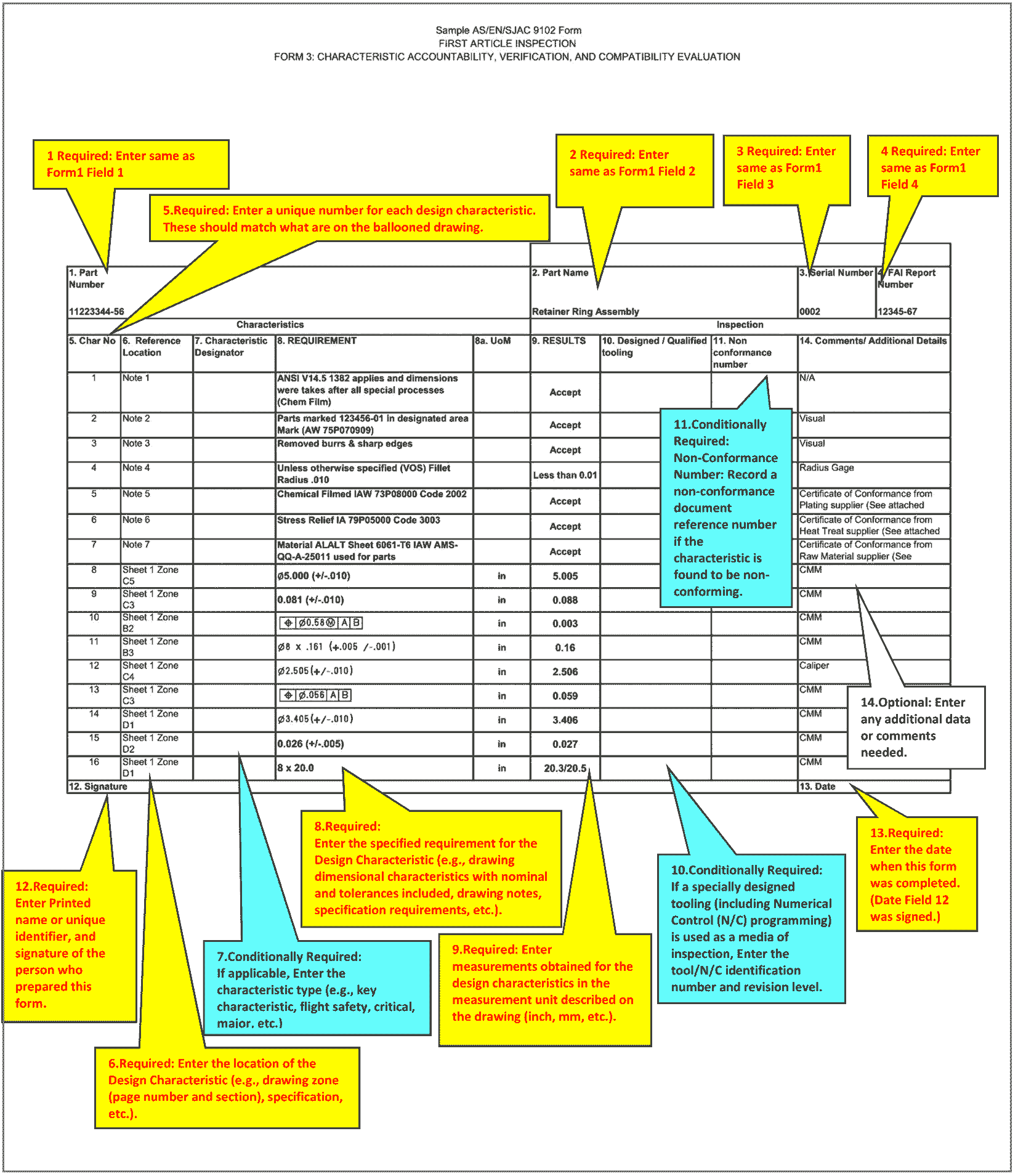

Web here's how you can create a first article inspection report in five steps. Customise the first article inspection form template to better suit your report format with. Learn more about as9102 and download a free as9102 rev b template and this guide as a pdf. 2) first article inspection as9102 form 1; Bill of materials/raw materials list; This article is a detailed example of how to fill out all 3 forms of the as9102 first article inspection report. Before beginning, gather the documentation needed for your first article inspection: Web the purpose of first article inspection (fai) is to validate (1) seller’s product realization processes are capable of producing parts and assemblies that meet all engineering and design requirements, and (2) those processes are stable and repeatable. A well planned and well executed fai will provide 1) first article inspection (fai) report;

A first article inspection (fai) is a business process that determines whether the manufacturing process for a part is capable of consistently delivering parts that conform to specifications. 3) first article inspection as9102 form 2; Web here's how you can create a first article inspection report in five steps. Download free first article inspection as9102b template & input guide. 2) first article inspection as9102 form 1; A well planned and well executed fai will provide Learn more about as9102 and download a free as9102 rev b template and this guide as a pdf. They then compare them to the client specifications to verify they match exactly. Before beginning, gather the documentation needed for your first article inspection: Web sae as9102 first article inspection form form 2:

First Article Inspection Template Excel Form Fill Out and Sign

Material or process name 6. They then compare them to the client specifications to verify they match exactly. 1) first article inspection (fai) report; Web here's how you can create a first article inspection report in five steps. This article is a detailed example of how to fill out all 3 forms of the as9102 first article inspection report.

How to Fill Out an AS9102 First Article Inspection Report with Excel

They then compare them to the client specifications to verify they match exactly. Web the purpose of first article inspection (fai) is to validate (1) seller’s product realization processes are capable of producing parts and assemblies that meet all engineering and design requirements, and (2) those processes are stable and repeatable. Web sae as9102 first article inspection form form 2:.

Form AS9102 First Article Inspection

Web the purpose of first article inspection (fai) is to validate (1) seller’s product realization processes are capable of producing parts and assemblies that meet all engineering and design requirements, and (2) those processes are stable and repeatable. 1) first article inspection (fai) report; Digital product definition data sets; Material or process name 6. And 5) first article inspection checklist.

AS/EN/SJAC 9102 Rev A First Article Inspection Sheet

Web in the aerospace and defense industry, the as9102 first article inspection is the standard. Web instructions first article inspection (fai) report for form mdc 1016 1. 2) first article inspection as9102 form 1; Part nu mber 2 part name 3. This article is a detailed example of how to fill out all 3 forms of the as9102 first article.

How to Fill Out an AS9102 First Article Inspection Report with Excel

Web in the aerospace and defense industry, the as9102 first article inspection is the standard. Web top 5 first article inspection forms & fai reports: Before beginning, gather the documentation needed for your first article inspection: 3) first article inspection as9102 form 2; Customise the first article inspection form template to better suit your report format with.

ISO 13845 First Article Inspection Medical Device FAI FDA 21 CFR

Web in the aerospace and defense industry, the as9102 first article inspection is the standard. Web top 5 first article inspection forms & fai reports: They then compare them to the client specifications to verify they match exactly. 3) first article inspection as9102 form 2; This article is a detailed example of how to fill out all 3 forms of.

First Article Inspection (FAI) The Beginner's Guide for 2022

1) first article inspection (fai) report; And 5) first article inspection checklist. This article is a detailed example of how to fill out all 3 forms of the as9102 first article inspection report. Web the purpose of first article inspection (fai) is to validate (1) seller’s product realization processes are capable of producing parts and assemblies that meet all engineering.

Sheet 1 of 3 First Article Inspection Report Form 1 Part Number

Web top 5 first article inspection forms & fai reports: Material or process name 6. 4) first article inspection as9102 form 3; 1) first article inspection (fai) report; They then compare them to the client specifications to verify they match exactly.

First Article Inspection FORM 1 KITARON Quality Assurance System

They then compare them to the client specifications to verify they match exactly. Bill of materials/raw materials list; Web sae as9102 first article inspection form form 2: 2) first article inspection as9102 form 1; A well planned and well executed fai will provide

Part Inspection Report Template Best Layout Templates

They then compare them to the client specifications to verify they match exactly. 4) first article inspection as9102 form 3; Digital product definition data sets; Web sae as9102 first article inspection form form 2: 1) first article inspection (fai) report;

Web Here's How You Can Create A First Article Inspection Report In Five Steps.

1) first article inspection (fai) report; Bill of materials/raw materials list; Web download, print or send your completed first article inspection reports as professionally formatted pdf documents with your company logo and colours. A well planned and well executed fai will provide

And 5) First Article Inspection Checklist.

Web sae as9102 first article inspection form form 2: Web in the aerospace and defense industry, the as9102 first article inspection is the standard. Part nu mber 2 part name 3. 4) first article inspection as9102 form 3;

Material Or Process Name 6.

Download free first article inspection as9102b template & input guide. Digital product definition data sets; What is a first article inspection (fai)? 3) first article inspection as9102 form 2;

Before Beginning, Gather The Documentation Needed For Your First Article Inspection:

Web top 5 first article inspection forms & fai reports: 2) first article inspection as9102 form 1; Web the purpose of first article inspection (fai) is to validate (1) seller’s product realization processes are capable of producing parts and assemblies that meet all engineering and design requirements, and (2) those processes are stable and repeatable. They then compare them to the client specifications to verify they match exactly.