Interlocking Sheet Metal Joints

Interlocking Sheet Metal Joints - Sheet metal parts can be connected to each other by folding or bending tabs in the form of a buckle and a clamping slot. This method of assembly is. There are 3 forces to consider when designing interlocking joints: Web designing for interlocking joints. Screw joint is a type of temporary joint. Web sheet metal joining methods 1. Folding / tab sheet metal joints. The tighter the joint is, the higher the friction and the. Screw joint in sheet metal. Screws, bolts, nuts, studs, and standoff are used for fastening sheet.

Screws, bolts, nuts, studs, and standoff are used for fastening sheet. Web sheet metal joining methods 1. Screw joint in sheet metal. There are 3 forces to consider when designing interlocking joints: Sheet metal parts can be connected to each other by folding or bending tabs in the form of a buckle and a clamping slot. Screw joint is a type of temporary joint. This method of assembly is. Web designing for interlocking joints. Folding / tab sheet metal joints. The tighter the joint is, the higher the friction and the.

The tighter the joint is, the higher the friction and the. There are 3 forces to consider when designing interlocking joints: This method of assembly is. Sheet metal parts can be connected to each other by folding or bending tabs in the form of a buckle and a clamping slot. Web sheet metal joining methods 1. Screws, bolts, nuts, studs, and standoff are used for fastening sheet. Folding / tab sheet metal joints. Screw joint in sheet metal. Web designing for interlocking joints. Screw joint is a type of temporary joint.

Interlocking Panel Steeline Australia All your steel solutions

The tighter the joint is, the higher the friction and the. There are 3 forces to consider when designing interlocking joints: Sheet metal parts can be connected to each other by folding or bending tabs in the form of a buckle and a clamping slot. This method of assembly is. Screw joint in sheet metal.

Flexible Interlocking Steel Joint System Rustic Industrial, Industrial

There are 3 forces to consider when designing interlocking joints: Folding / tab sheet metal joints. The tighter the joint is, the higher the friction and the. Screw joint is a type of temporary joint. Web designing for interlocking joints.

How to Install Flush Panel Concealed Clip YouTube

Screw joint in sheet metal. Web sheet metal joining methods 1. The tighter the joint is, the higher the friction and the. Screws, bolts, nuts, studs, and standoff are used for fastening sheet. This method of assembly is.

Flexible Interlocking Steel Joint System Joinery, Jets and Steel

This method of assembly is. Web sheet metal joining methods 1. Folding / tab sheet metal joints. Screw joint in sheet metal. Web designing for interlocking joints.

Clinching for Sheet Metal Assembly 20160505 Assembly Magazine

Folding / tab sheet metal joints. This method of assembly is. Screw joint in sheet metal. Screws, bolts, nuts, studs, and standoff are used for fastening sheet. The tighter the joint is, the higher the friction and the.

Salvagnini sheet metal bending Salvagnini metal panel bending

The tighter the joint is, the higher the friction and the. This method of assembly is. Sheet metal parts can be connected to each other by folding or bending tabs in the form of a buckle and a clamping slot. Web designing for interlocking joints. Screw joint is a type of temporary joint.

Flexible Interlocking Steel Joint System Metal furniture design

Folding / tab sheet metal joints. Screw joint is a type of temporary joint. Web designing for interlocking joints. This method of assembly is. Sheet metal parts can be connected to each other by folding or bending tabs in the form of a buckle and a clamping slot.

sheet metal joints Google Search Sheet metal, Sheet metal

Web designing for interlocking joints. Screw joint is a type of temporary joint. Screw joint in sheet metal. There are 3 forces to consider when designing interlocking joints: Folding / tab sheet metal joints.

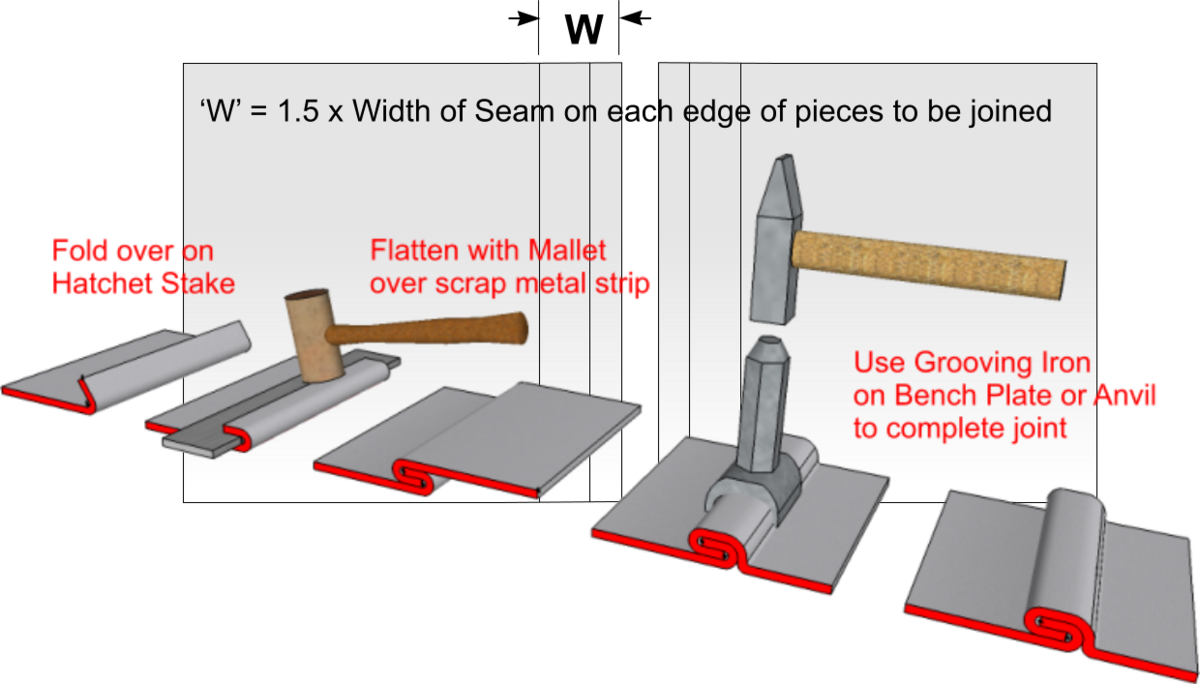

Grooved Seam Joint DT Online

There are 3 forces to consider when designing interlocking joints: The tighter the joint is, the higher the friction and the. Screws, bolts, nuts, studs, and standoff are used for fastening sheet. Sheet metal parts can be connected to each other by folding or bending tabs in the form of a buckle and a clamping slot. Folding / tab sheet.

How to design interlocking joints for fastening 3D printed parts Hubs

This method of assembly is. Web designing for interlocking joints. Folding / tab sheet metal joints. Screws, bolts, nuts, studs, and standoff are used for fastening sheet. Sheet metal parts can be connected to each other by folding or bending tabs in the form of a buckle and a clamping slot.

Screw Joint Is A Type Of Temporary Joint.

Web designing for interlocking joints. This method of assembly is. Screw joint in sheet metal. Web sheet metal joining methods 1.

Screws, Bolts, Nuts, Studs, And Standoff Are Used For Fastening Sheet.

Sheet metal parts can be connected to each other by folding or bending tabs in the form of a buckle and a clamping slot. There are 3 forces to consider when designing interlocking joints: The tighter the joint is, the higher the friction and the. Folding / tab sheet metal joints.