Roll Forming Sheet Metal

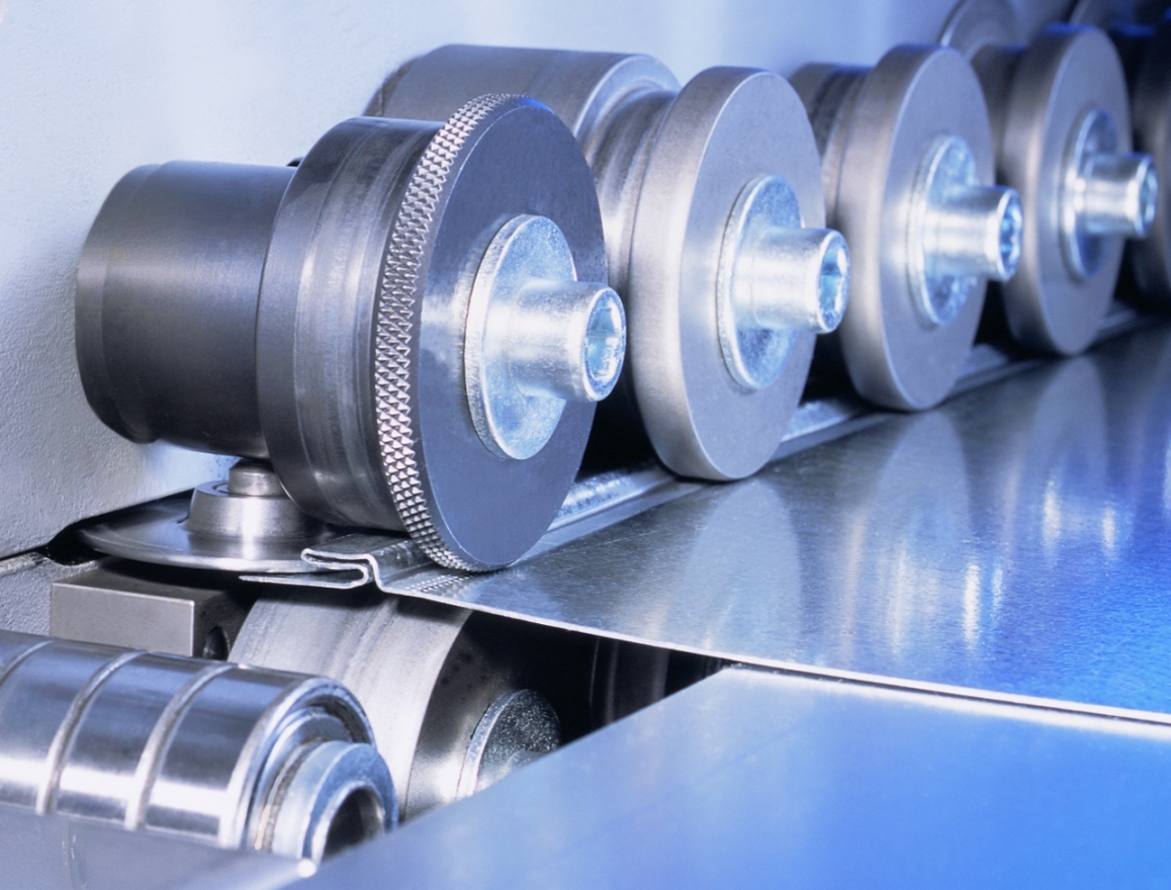

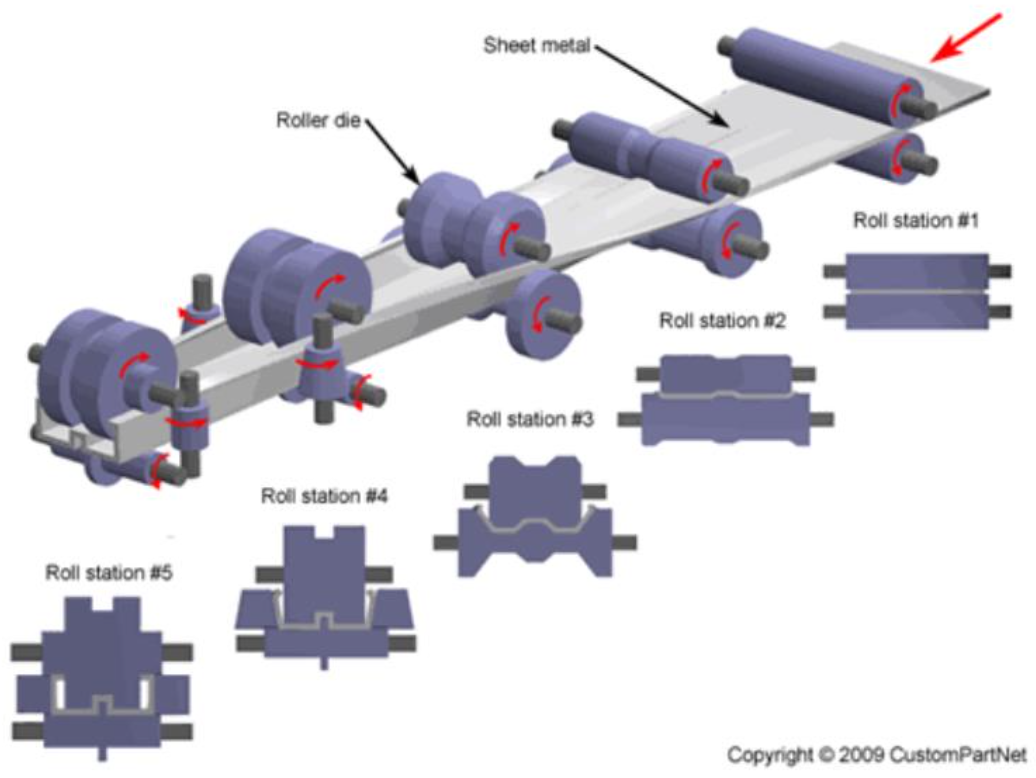

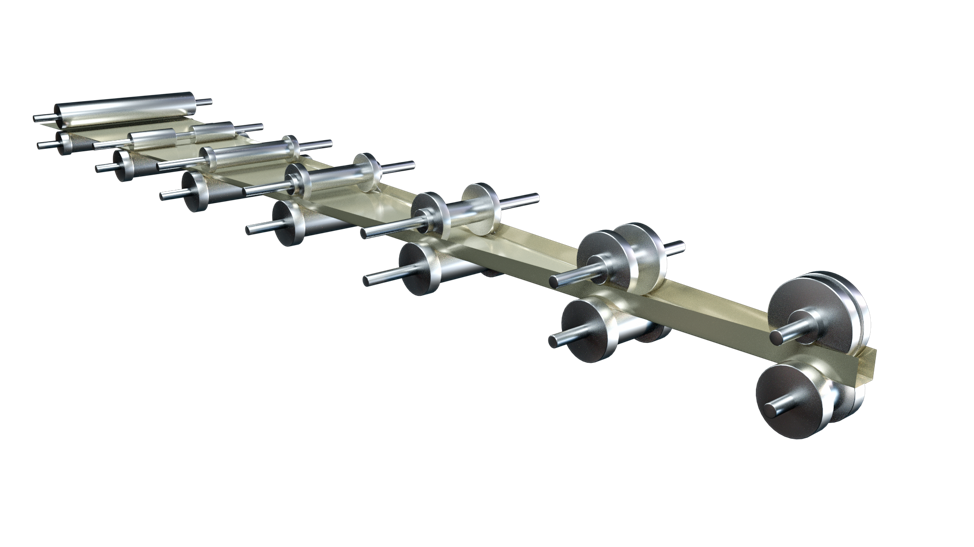

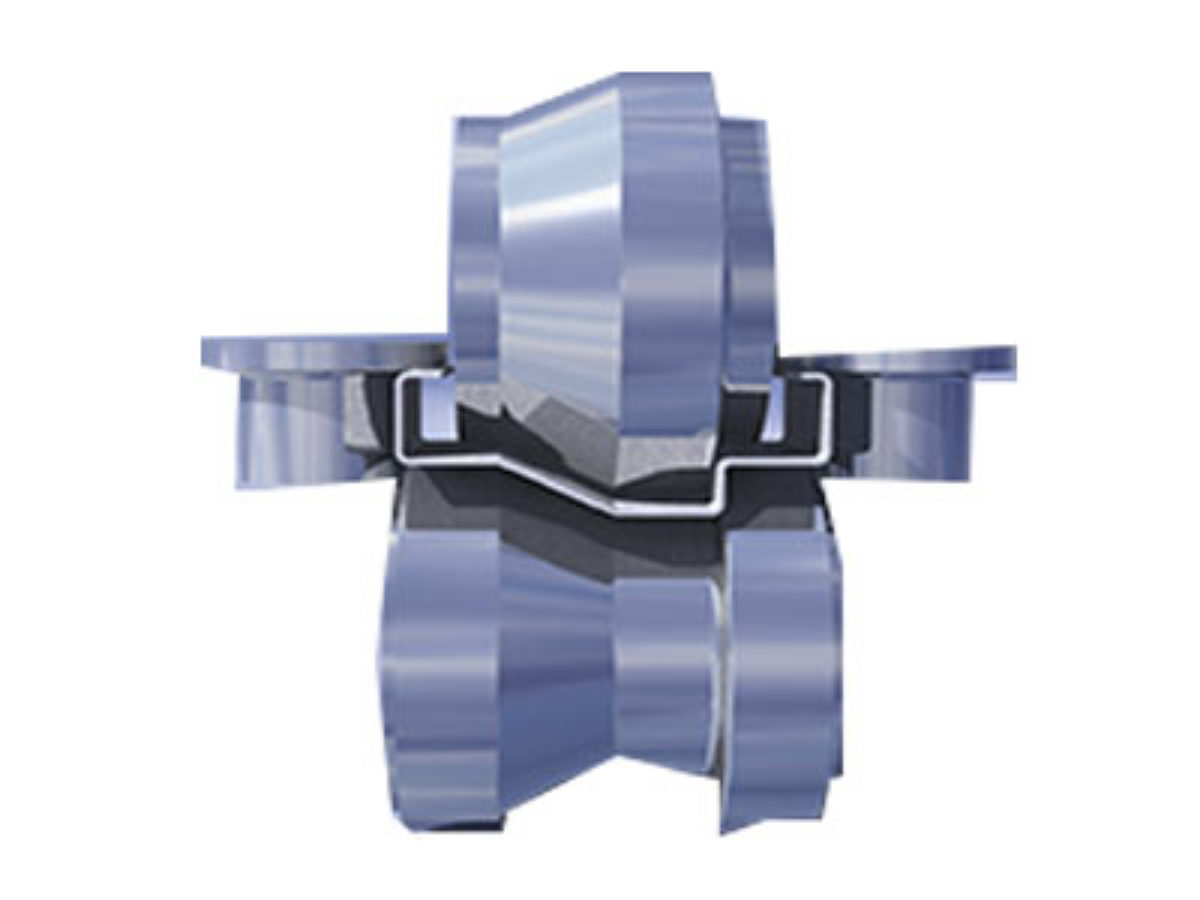

Roll Forming Sheet Metal - The forming on a roll former occurs as the sheet metal. Web roll forming is a metalworking process that shapes flat metal sheets or strips into complex profiles. Roll forming, on the other hand, is a continuous metal forming process that. Web in the roll forming process, a strip of metal is fed through a series of mated roll dies that are installed onto the shafts of a mill’s forming stands. Web any time the sheet metal is changed on a roll forming line, it is carried out by the roll former’s tooling. Web roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only.

Web roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only. Web roll forming is a metalworking process that shapes flat metal sheets or strips into complex profiles. Web any time the sheet metal is changed on a roll forming line, it is carried out by the roll former’s tooling. Roll forming, on the other hand, is a continuous metal forming process that. The forming on a roll former occurs as the sheet metal. Web in the roll forming process, a strip of metal is fed through a series of mated roll dies that are installed onto the shafts of a mill’s forming stands.

Web roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only. The forming on a roll former occurs as the sheet metal. Web any time the sheet metal is changed on a roll forming line, it is carried out by the roll former’s tooling. Roll forming, on the other hand, is a continuous metal forming process that. Web roll forming is a metalworking process that shapes flat metal sheets or strips into complex profiles. Web in the roll forming process, a strip of metal is fed through a series of mated roll dies that are installed onto the shafts of a mill’s forming stands.

Corrugated Metal Sheet Round wave Roll Forming Machine_steel rolling

Web any time the sheet metal is changed on a roll forming line, it is carried out by the roll former’s tooling. Web roll forming is a metalworking process that shapes flat metal sheets or strips into complex profiles. Web roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls,.

Sheet Metal Roll Forming Stainless Steel Roll Forming in NY

Web roll forming is a metalworking process that shapes flat metal sheets or strips into complex profiles. Web in the roll forming process, a strip of metal is fed through a series of mated roll dies that are installed onto the shafts of a mill’s forming stands. The forming on a roll former occurs as the sheet metal. Web any.

Roll Forming as a Bending Process in Metal Fabrication

Web roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only. Roll forming, on the other hand, is a continuous metal forming process that. The forming on a roll former occurs as the sheet metal. Web in the roll forming process, a strip of metal.

Roll Forming Metal Components Standard & Custom Roll Forming

The forming on a roll former occurs as the sheet metal. Web roll forming is a metalworking process that shapes flat metal sheets or strips into complex profiles. Web in the roll forming process, a strip of metal is fed through a series of mated roll dies that are installed onto the shafts of a mill’s forming stands. Web roll.

Sheet Metal Rolling for Commercial Applications

The forming on a roll former occurs as the sheet metal. Web in the roll forming process, a strip of metal is fed through a series of mated roll dies that are installed onto the shafts of a mill’s forming stands. Web roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of.

Manufacturing Sheet Metal Forming 123 DESIGN

Roll forming, on the other hand, is a continuous metal forming process that. Web in the roll forming process, a strip of metal is fed through a series of mated roll dies that are installed onto the shafts of a mill’s forming stands. The forming on a roll former occurs as the sheet metal. Web roll forming is a metalworking.

Sheet Metal Roll Forming Machines Supplier Believe Industry

Web any time the sheet metal is changed on a roll forming line, it is carried out by the roll former’s tooling. The forming on a roll former occurs as the sheet metal. Roll forming, on the other hand, is a continuous metal forming process that. Web in the roll forming process, a strip of metal is fed through a.

Roll Forming Design Guide for Sheet Metal Components

Web roll forming is a metalworking process that shapes flat metal sheets or strips into complex profiles. Web roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only. Web in the roll forming process, a strip of metal is fed through a series of mated.

What is Roll Forming? National Material Company Steel Processing

The forming on a roll former occurs as the sheet metal. Web roll forming is a metalworking process that shapes flat metal sheets or strips into complex profiles. Web in the roll forming process, a strip of metal is fed through a series of mated roll dies that are installed onto the shafts of a mill’s forming stands. Roll forming,.

In den Ruhestand gehen Die Stadt Leopard sheet metal rolling machine

The forming on a roll former occurs as the sheet metal. Web roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only. Web in the roll forming process, a strip of metal is fed through a series of mated roll dies that are installed onto.

The Forming On A Roll Former Occurs As The Sheet Metal.

Roll forming, on the other hand, is a continuous metal forming process that. Web roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only. Web in the roll forming process, a strip of metal is fed through a series of mated roll dies that are installed onto the shafts of a mill’s forming stands. Web roll forming is a metalworking process that shapes flat metal sheets or strips into complex profiles.